QC & Packing

Quality checks, at every stage of production, are an integral part of our processes. Packing is handled by a dedicated team trained to understand potential vulnerable areas in every model we produce and reinforce them to ensure that chances of damage during transit are negligible.

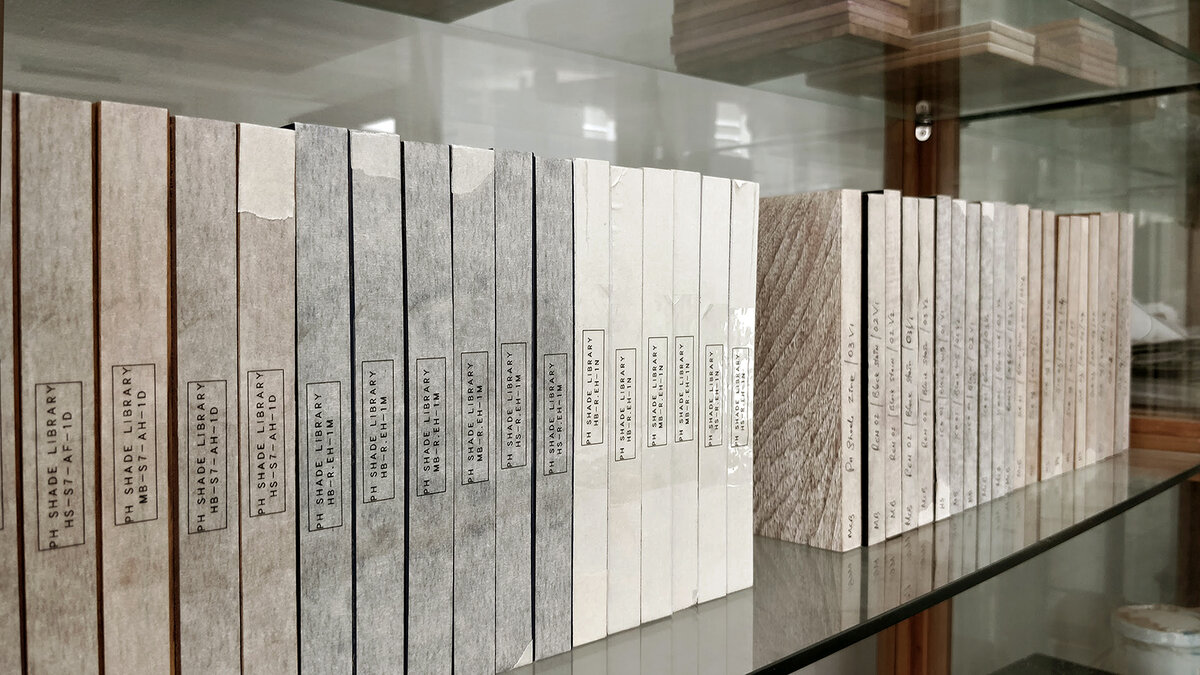

We are stringent about quality checks at every stage. Each department - carpentry, polishing, cane weaving, upholstery and packing - has its own supervisor responsible for quality control. Supervisors are trained to spot issues with both materials and processes. They work with rigorous checklists to make sure nothing is missed out.

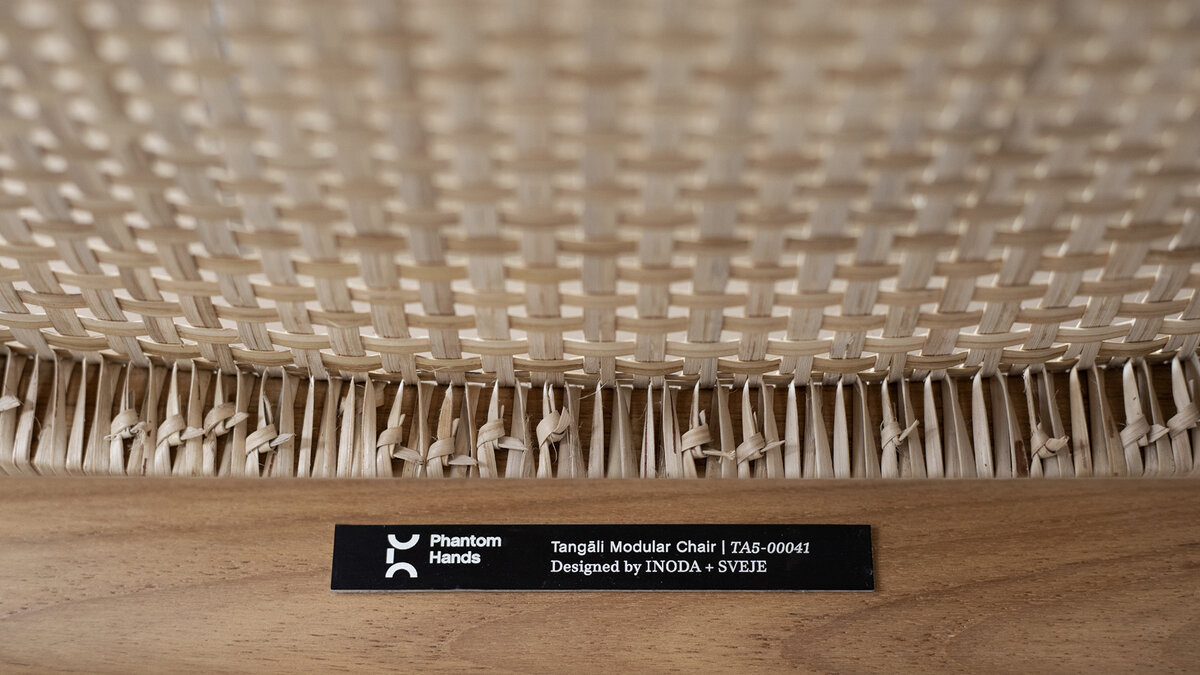

The final quality check before a consignment is packed is the most rigorous one that involves three rounds of checking following which a label with a unique identification number is attached to every product. Every piece of furniture is signed off by our Quality Control Head before it is packed.

Packaging design is as important to us as product design. Our packing boxes are custom designed to ensure a safe and comfortable ride for each piece of furniture we ship. Packing is handled by a dedicated team trained to understand potential vulnerable areas in every model we produce and reinforce them to ensure that chances of damage during transit are negligible. By using reinforced cardboard boxes, reusable cloth bags, biodegradable wrapping and PET straps, we try to reduce the environmental impact of our packaging. For a quick snapshot of our packaging process, watch this video.