Wood Finishing

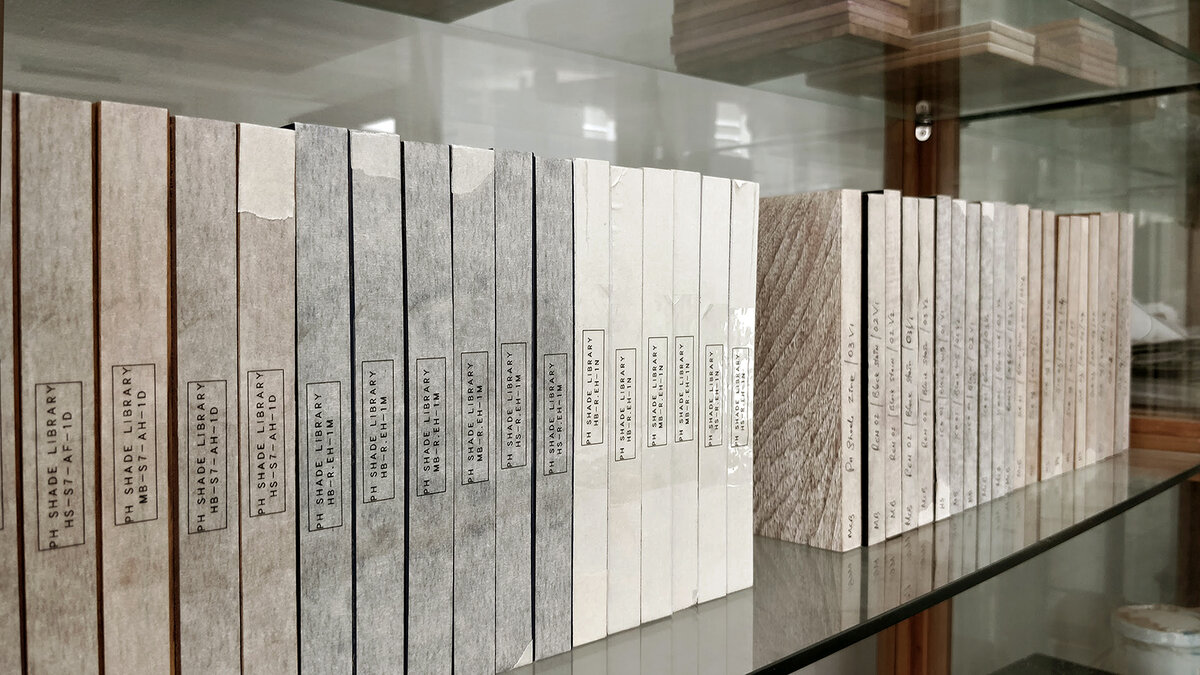

Our furniture is polished and finished almost entirely by hand. The wood is sanded with different grades of sandpaper, polished, stained, and sealed in layers. The process is repeated multiple times to get our distinctive finish.

Traditionally, wood polishing is a specialised function in India, distinct from carpentry. Communities that practice wood polishing are also skilled at painting walls and interiors. Several of our wood polishers are from a single family - originally from Gorakhpur in Uttar Pradesh.

Our furniture is polished and finished almost entirely by hand. The wood is sanded with different grades of sandpaper, and then polished, stained and sealed in layers. The process is repeated multiple times to get a distinctive finish.

Our distinctive Natural Teak finish is obtained by hand applying shellac, a natural wood finish that is non-toxic and has been used for centuries in woodworking.

We constantly update the paint and polish materials we use in our endeavour to make our products more eco-friendly and safe for our artisans and our customers. For instance, we have moved away from polyurethane paints to water-based stains for our black finish.